The SMF AR system is ideally suited toward applications with deviating application profiles and frequently low exhaust gas temperatures. These low temperature applications are more commonly found on construction sites, on mobile machines and static equipment. The SMF AR System (Sintered Metal Filter with Active Regeneration) regenerates autonomously regardless of the exhaust gas temperature.

HJS SMF®-ER

Construction vehicles cause a considerable amount of air pollution on construction sites. As a result, there is an ever increasing demand for the use of particulate filters, especially within urban areas.

HJS offers a flexible, robust and effective alternative to an immovable DPF® system. The SMF®-ER is quick and easy to install, and can be interchanged with several other machines. The regeneration or cleansing can be performed on site, while the machine is running with a second filter unit.

Advantages of SMF AR

- Reduction of soot and ultra-fine particles by more than 99%

- Filter regeneration at low exhaust gas temperatures

- Regeneration without using a Diesel Oxidation Catalyst (DOC) enabling operation with high sulphur content fuel

- Flexible adaptation to different machines and engine powers outputs

- High ash storage capability ensures long service life

- The modular assembly facilitates dismantling of the system for service

HJS interchangeable filter system SMF®-ER

The HJS SMF®-ER is designed for quick and easy installation on the machine on-site. All necessary components from our modular system portfolio can be constellated according to the intended use, enabling the individual configuration of each filter on all of the fitted machines.

The filter is fixed to the machine mounted base plate via quick release clamps.

Advantage: The use of identiacal base plates on multiple machines allows you to quickly and easily switch the filter unit from one machine to the other.

The inlet and outlet cones have been designed for an optimal exhaust gas flow, resulting in the complete utilization of the filter unit. The soot level can be easily monitored with the affixed pressure manometer.

Cleaning intervals depend on the engine condtion, operation and driving conditions. The filter should be cleaned in an enclosed container with pure water. Waste water must be properly disposed according to waste code 161002

For more information contact please contact HJS

Your Advantages

- Quick and easy installation

- Cost efficient

- Individual usage and interchangeable

- Simple handling – short changeover times via quick release clamps

- High soot capacity compared to other conventional filter systems

- Pressure monitored for easy inspection

- Regeneration or cleansing apart from the machine

- Easily cleanable with water

- Extra durable design

- Built for rough construction site conditions

- In-house development and manufacturing

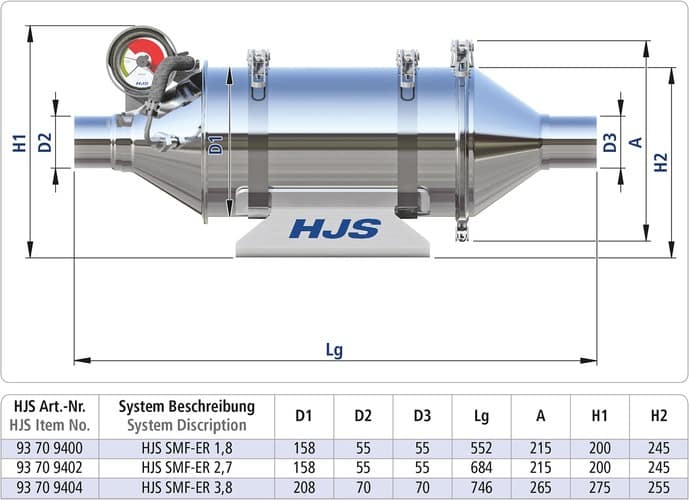

HJS SMF-ER 1,8