Performance of the first electric 5-axle truck

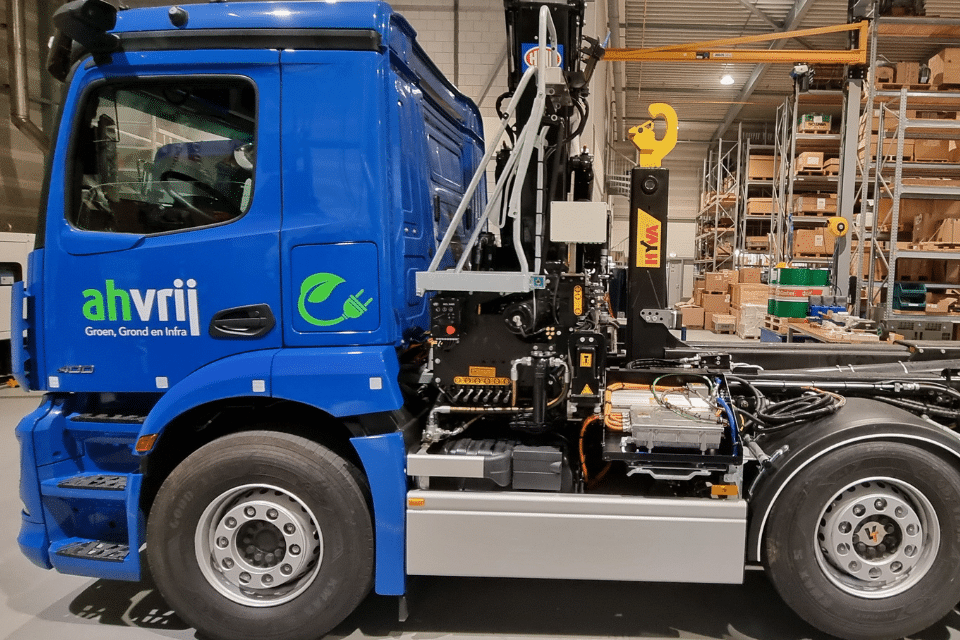

In 2023, Veldhuizen Trucks had a world first: the company successfully built the first electric 5-axle truck. The basis for the electric tipper is a Mercedes Benz E-Actros 400 6×2. Veldhuizen carried out various modifications to convert the truck into a Veldhuizen Trucks 10×2. The tipper body was then provided by Hyva, after which DLS installed a Parker ePTO system for the hydraulic control.

Veldhuizen Trucks specializes in the conversion of heavy-duty trucks. Their experienced team performs truck modifications on ramp trucks and construction vehicles, building customized trucks with minimal adjustments. The company also produces in stock and for its own rental fleet. This allows them to respond quickly to customer demand, which is a major advantage in times of “vehicle shortage”.

According to Evert Hennipman of Veldhuizen Trucks, the company chose to add an electric tipper to their fleet due to increasing demand. “The demand for zero emission is there every day, but the existing vehicle configurations from the ‘big brands’ do not offer a complete alternative for the construction transport for which we convert vehicles. There we saw opportunities to modify an existing truck into an electric tipper. The fact that we can produce it for our own rental fleet makes it easier for us to bring a prototype to the market.”

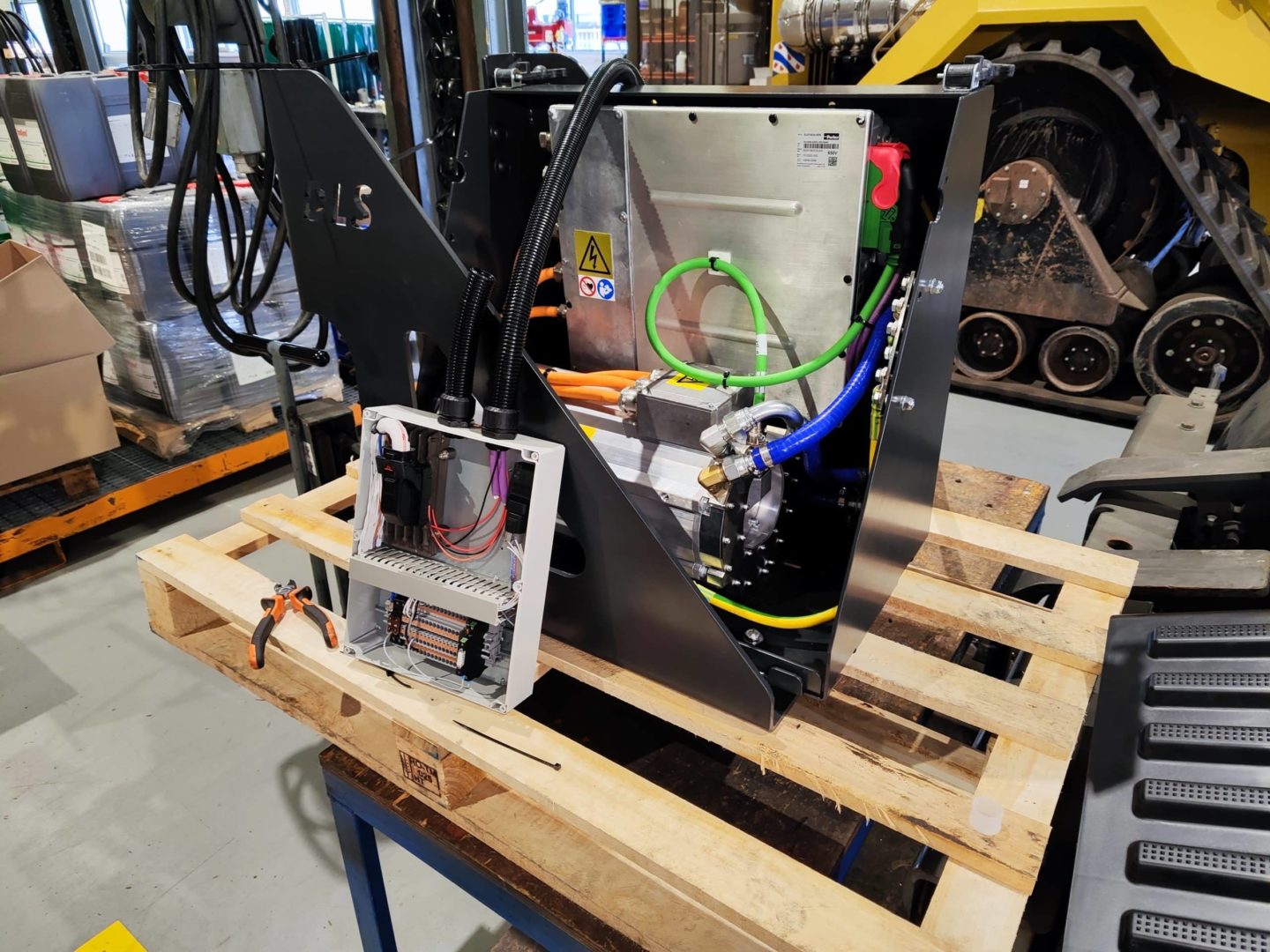

The conversion of an electric truck also meant that an alternative had to be found for the traditional hydraulic control via a PTO. This was found in the Parker ePTO. Evert Hennipman: “Our research into available ePTOs ultimately gave us two options. The choice for the Parker ePTO was mainly due to the local involvement of DLS as a system integrator.”

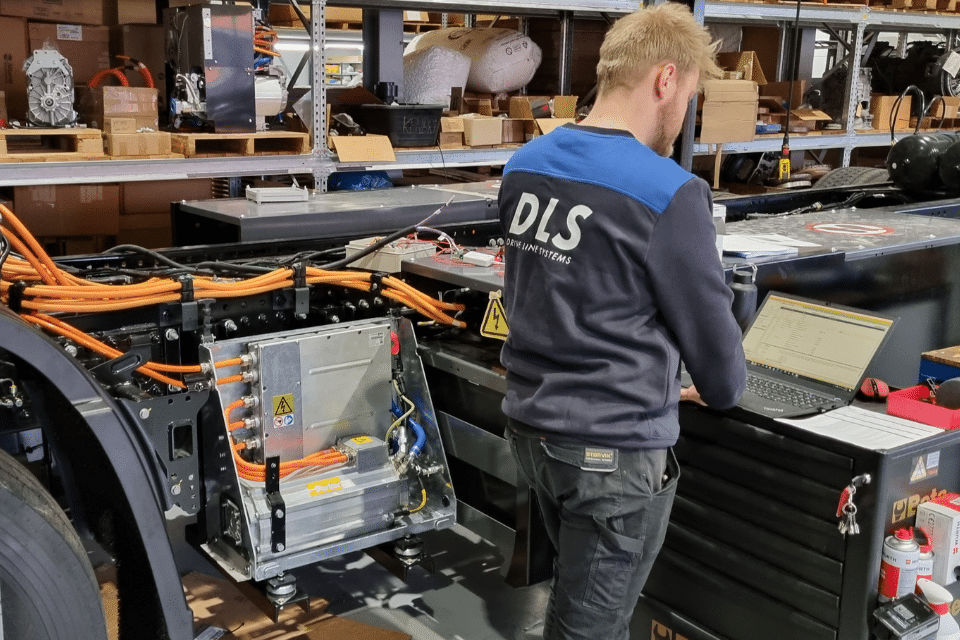

DLS installed a Parker ePTO system, consisting of an electric motor driven by an inverter. The inverter is powered by a DC power source, in this case the battery pack of the electric truck. The system is built into a special frame, which allows it to fit exactly into the available space. DLS engineers then carried out the CAN bus integration for optimal communication with the vehicle. This ensures maximum safety and the possibility of operating the ePTO from the vehicle. Finally, the system was assembled and the e-motor and inverter were configured during commissioning.

Evert Hennipman: “Initially, we were moderately positive and somewhat hesitant about the ePTO. By the way, like many others in the market, we were a bit hesitant about the entire concept of electric drive. But it turned out to be a complete product that is mounted as a kit against the chassis. Another big advantage is that it is easy to set various speeds as desired.”

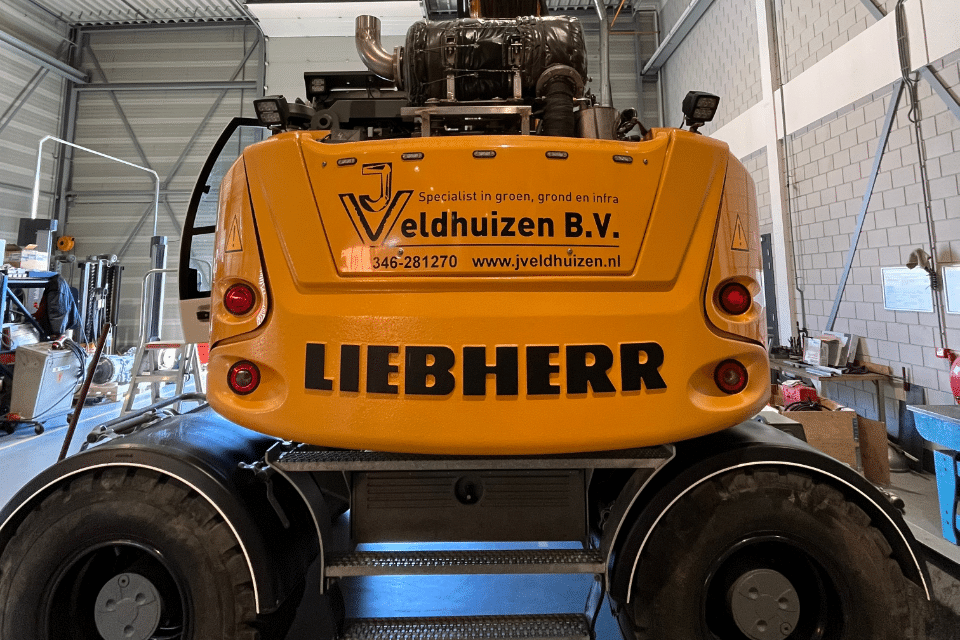

Since 2023 several customers of Veldhuizen Trucks have used the electric tipper, including J. Veldhuizen B.V., specialist in green, soil and infrastructure. Director Jaap Veldhuizen: “We chose the electric tipper from Veldhuizen Trucks because of the client’s requirement to carry out the work as emission-free as possible.” Overall, the experience of J. Veldhuizen B.V. was positive. “We were not so concerned about the performance of the tipper. We also have other electrical equipment and that generally works well. The truck drives well and has a lot of comfort. The tipping also worked well, the ePTO system did not cause any malfunctions and works very well. A traditional PTO has slightly more liters, which means you can perhaps tip a little faster, but that difference is very small and hardly noticeable.”

Do you want to know more about the Veldhuizen Trucks electric tipper? Click here to view the specifications (in Dutch).